Dyneema and nylon slings

Nylon (polyamide) and Dyneema®/Spectra® (polyethylene) are two synthetic raw materials with distinct strengths and weaknesses used in the manufacture of slings and quickdraws. Understanding the properties of these man-made fibres will guide us to best practice at the crag for using such products.

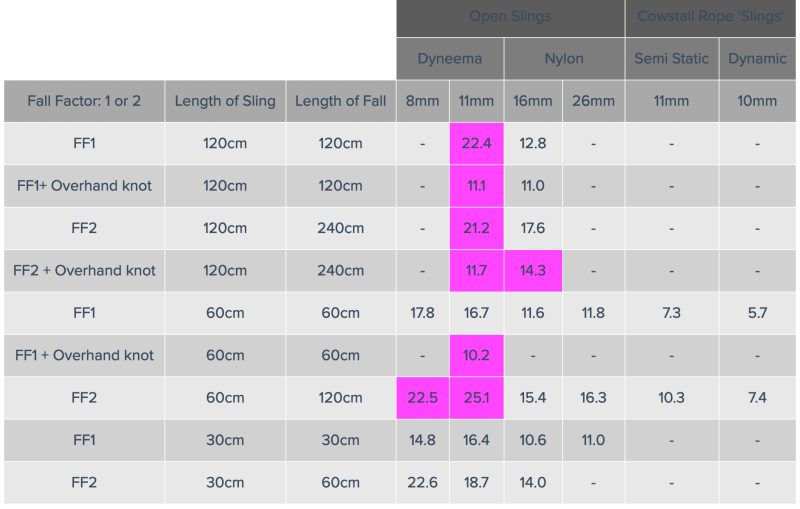

While Dyneema® has a much greater strength-weight ratio (static load) than nylon, its elasticity is far less. At DMM’s test-tower we took a look to see what implications this difference has for a dynamic loading on to a Dyneema® sling and what happens if there is a knot in the sling? You can see the comparative results between Nylon and Dyneema® slings (all rated at 22 kN) in this video and in the table below.

After watching the video I’m sure you’ll agree that dogging a move on a sport climb while clipped to any sling is a dangerous idea and that having any slack in a belay system is best avoided – you wouldn’t want to fall off a ledge clipped into a slack sling.

Even a 60 cm fall-factor 1 fall on to an open Dyneema® sling can generate enough impact force (16.7 kN) at the anchor to pull a Wallnut 11 wire (12 kN) apart. Tying a knot in a Dyneema® sling weakens it even further leading to sling failure in a fall-factor 1 loading on to a 120 cm sling.

For perspective, most leader falls are between 4 – 7 kNs. Forces above 10kN will start to cause internal injuries – 10kN equates to 1 metric tonne in ‘old money’.

It is also important to bear in mind that the characteristics of slings and quickdraws are also affected by the weave and blending of fibres, purposefully used to achieve particular handling qualities. Dyneema® slings are in fact usually a blend of nylon and Dyneema® fibres.

While the impact forces in the tests for the nylon slings are lower than the Dyneema® they were still high enough to snap wires. This isn’t to say Dyneema® is bad and nylon is good. On the contrary, comparing the two materials, Dyneema® has a strength to weight ratio higher than not just nylon but also steel, a significantly higher resistance to cutting and lower water absorbtion (important in winter), making it an ideal material for slings and quickdraws. It is also more resistant to ultra-violet rays and chemical attack than nylon but has a lower melting point. This is an important factor to consider when abseiling – pulling a rope through a Dyneema® sling, say as in poor abseiling practice, will generate enough heat to severely weaken the sling, if not melt through it.

It’s knowing these properties and making an informed choice according to your needs as a climber that is important. Clearly, taking advantage of the shock-absorbing capability of the rope by using it to tie directly into anchors as opposed to using a sling, will reduce the chances of dramatically shock-loading the anchors. If you do use slings then ensuring there is no slack in the system is paramount.