Twisting ring

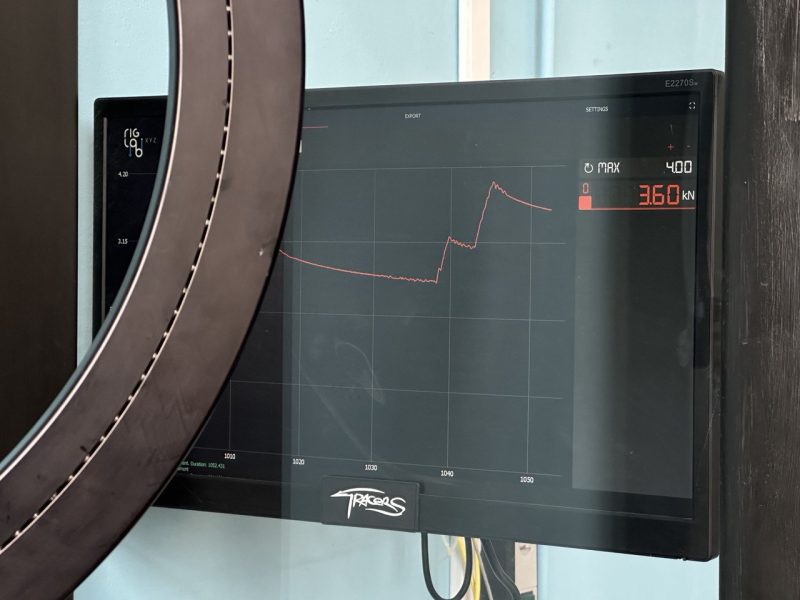

First test below shows breaking test of assembled* inner and outer ring.

Result: 59.76 kN (6093 kgf, 13434 lbf)

* Raw aluminium color, no finishing. Swivel and sizing units are not installed. This fact does not affect the ring load test. We installed steel plates to simulate the behaviour when units are on the ring.

On the second test we are applying 50kN to swivel unit.

Result: Swivel is still ok after 51.36 kN (5958 kgf, 11465 lbf)

Swivel after test still spinning well, 10mm marine shackle bent over.

We have also ran inner/outer rings spinning test under the load limit according to ring’s WLL (check manual and tech specs).

* On photos you can see some steel parts without blackening (no surface treatment). But the final product is all black.

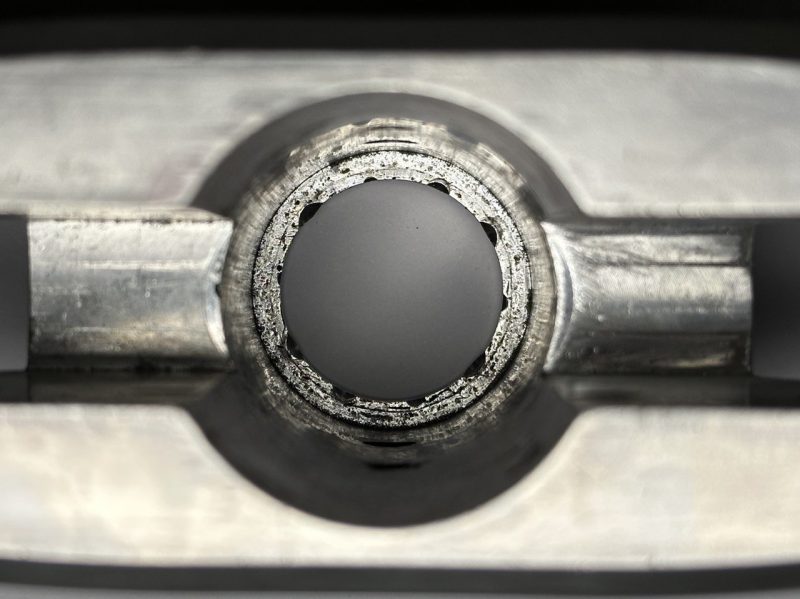

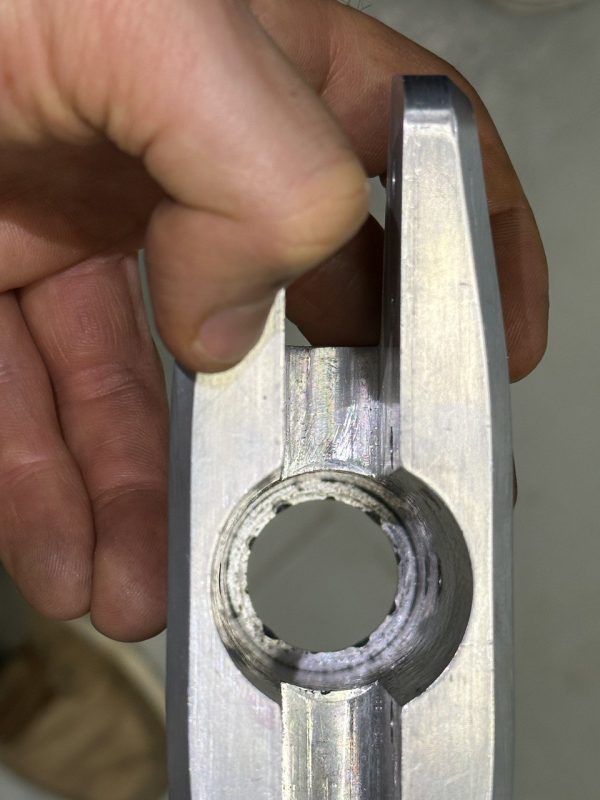

What if trust bearing we are using in the swivel nodes of the ring will be installed in a wrong way?

We have tested this case and we ran test till bearing was destroyed but the construction of the swivel node prevented it from falling out. So you still can go up to 50kN even with wrong installed bearing. This case you will see few mm gap between the swivel head and the swivel node.

During our developing process the main focus is on safety. For the twisting ring then comes sizing, spinning speed, sound, overall size. Now we are working on brakes to control rotation speed. Soon we will publish first tests.

After field tests (check the video above) made by our great supporter and first Tracers Twisting Ring client Jayden Irving some issues with size adjuster were discovered and fixed.

We always open for comments and glad to get feedback as it helps in progress with development of new products.

Tracers archive